Akumulator wózka medycznego 12V50-SM: specjalnie zaprojektowany do komputera na kółkach/wózków medycznych/stacji roboczej lekarza/stacji roboczej pielęgniarki/wózka mobilnego, który może zastąpić U1-12RT, U1-40,U1-45,U1-50 i URB12400-U1-SMB

Akumulator wózka medycznego 12V50-SM: specjalnie zaprojektowany do komputera na kółkach/wózków medycznych/stacji roboczej lekarza/stacji roboczej pielęgniarki/wózka mobilnego, który może zastąpić U1-12RT, U1-40,U1-45,U1-50 i URB12400-U1-SMB

Akumulator do wózka medycznego SPF12V50-SM

Superpack SPF12V50-SM Lithium Iron Phosphate smart battery offers incredible performance in a wide range of transportable and stationary equipment, including medical carts, delivery robots etc.

The built-in battery management system(BMS) and RJ45 communication port allows host devices to communicate with the battery via SMBus. Important battery information such as Average Runtime to Empty (minutes), Relative State of Charge (%) and Cycle Count (#) is available enabling the battery to be an active part of any host device’s power management system. The battery is fully compliant with the requirements of inverter/chargers used in popular medical carts.

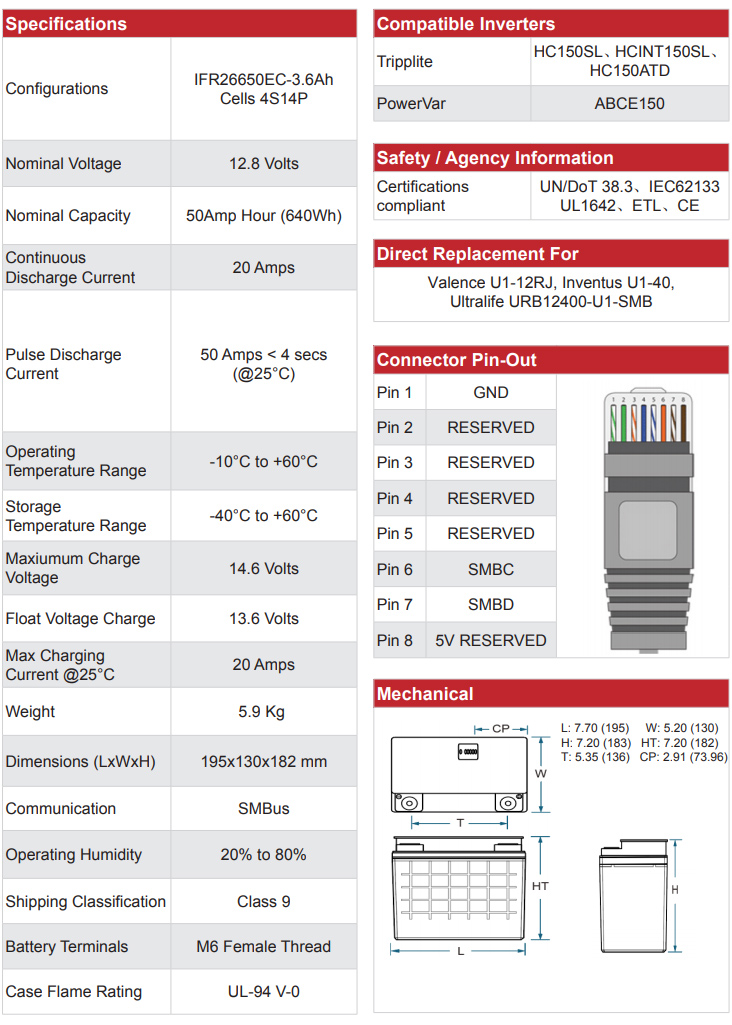

TECHNICAL SPECIFICATION

KEY FEATURES

• Stable voltage during discharge

• Pre-charge function enable battery recover from deep discharge status

• Significantly lighter than lead acid batteries for the same amount of energy

• Does not become gaseous during use

• Nominal voltage maintained over a wider temperature range

• Can be charged using a 2-phase sealed lead acid charger

• IEC 62133, 2nd edition compliant

• Designed to work with popular industry standard inverters used on medical carts

• SMBus communications interface

The SPF12V50-SM is specifically designed to replace and outperform lead acid batteries.

The tough, UL94V-0 flame retardant polycarbonate case ensures internal cells and electronics are protected at all times and unlike a lead acid battery the SPF12V50-SM can be mounted in any direction and does not require charging in a

vented area. When used in a cyclic application more than 2000 cycles are possible, making it a truly ‘fit & forget’ proposition for many applications. As safety is paramount, the SPF12V50-SM is designed with internal protection against

over-charge, over-discharge, over-current and over-temperature while a cell balancing system ensures the internal battery cells operate in unison, promoting a higher degree of safety, longer runtime per cycle and more cycles over life.

The SPF12V50-SM can be continuously discharged at currents up to 20A and pulsed at currents up to 50A. Regulatory compliance is assured as the SPF12V50-SM meets the requirements of UN38.3 (transportation) and is certified to ETL (safety). This means it can be easily incorporated into medical equipment certified to IEC 60601-1.

WARRANTY INFORMATION

The SPF12V50-SM has been manufactured under the most stringent of quality standards and is designed to provide outstanding performance over its life. Warrants the Product such that it will be free from defects in materials and workmanship and will furnish eighty percent (80%) of its rated capacity after the earlier of 2,000 cycles or 24 months from the date the Product was first shipped to the customer.

Superpack will repair or replace, at Superpack’s sole discretion, any Product which does not meet this warranty within the applicable period, provided the Product is delivered intact and prepaid to the location authorised by Superpack , and subject to the following: This warranty does not extend to equipment utilised with the Product, or to any Product which

Superpack determines, in its sole discretion, is not intact, on which seals have been broken or attempted to be broken, or which has been subjected to misuse, neglect, accident, tampering, alteration, augmentation, use with incompatible equipment or inconsistent with these instructions, or improper installation, or storage conditions, including, but not limited to, moisture or liquid exposure, proximity or other exposure to heat, or misapplication.

The foregoing is in lieu of all other warranties expressed, implied, statutory or otherwise. In no instance, whether within or outside the warranty period or under any circumstance,is or will Superpack be liable for any loss, damage, injury or expense of any kind or nature caused, directly or indirectly, as a result of having delivered a Product that does not perform as warranted, including, without limitation, any such loss, damage, injury or expense arising from use of the Product or any interruption or service or for any loss of business whatsoever or however caused, including but not limited to any lost profi ts or any indirect, special, punitive or consequential damages. The sole remedy shall be the repair or replacement of the Product. The customer is responsible for the proper packaging and shipping of the Product to

Superpack, together with proof of purchase, for review under this warranty. Shipping containers may be purchased from Superpack. Repaired or replaced Product will be shipped to the customer at no charge; however, any expedited shipping charges are the responsibility of the customer. The SPF12V50-SM Lithium Iron Phosphate battery contains a sophisticated BMS which constantly monitors the operation of the battery during charge, discharge and storage. This system ensures the battery remains safe under foreseeable abuse conditions. The BMS tracks and keeps a permanent record of pertinent electrical and environmental data for validating warranty claims.

The warranty shall be void if:

• The date on which the customer notifies Superpack of a possible warranty claim exceeds 24 months from the date the Product was first shipped to the customer.

• The Product has been cycled more than 2,000 times. The BMS tracks discharge activity and increments the cycle count when the cycle count threshold of 80% of design capacity has been reached. Cycle count is therefore an aggregate of all discharge activity.

• The voltage across the terminals of the Product exceeds 14.6V. Do not use any charger which has a charge voltage which exceeds this value. If the battery is to be used in a noncyclic (float) application, then the charge voltage should not exceed 13.6V.

• The internal cell voltage falls below 2V per cell. The BMS tracks minimum cell voltages to ensure proper battery storage conditions have been maintained. Do not store the battery in a discharged state. It should be fully charged before being put into storage.

• The charge current exceeds 20A. The Product can be safely charged at currents up to 20A however the recommended charge current is 10A. • The discharge current exceeds 20A. The Product can be safely discharged at currents up to 20A. The battery is not suitable for high current applications such as engine starting.

• The Product is charged at a temperature below 0°C or above a temperature of +45°C. The recommended charge temperature is +20°C.

• The Product is stored for more than 3 months (regardless of its state of charge) without any use. It is recommended that the battery is fully charged every 3 months.

• The Product is stored at a temperature below -40°C or above +60°C. The recommended storage temperature is +10°C to +30°C.

• Liquid or any other foreign material has entered the Product. Note that the communication port is not sealed and care should be taken to prevent ingress at this point.

• The Product label is removed, covered or tampered with. The Product label includes the date of manufacture and serial number which is required for warranty validation purposes.

• The Product shows signs of damage from mechanical abuse or modification.

• The Product has been opened or if any attempt has been made to open it. The Product contains no user serviceable parts.

• The communication port on the Product has been modified or damaged in anyway. Access to the electronic system via this connector is required for validating warranty claims.

• Damage to the positive or negative terminals of the Product has been caused by incorrect connection of external electrical terminals. Only ring terminals designed for M6 screws should be used and the supplied screws must be tightened to a torque of 8 Newton Meters. The use of fork terminals is not recommended.

Request for Quotation

Request for Quotation